|

| |

Navigation through this site is

by process type with an emphasis on equipment

| |

|

Power

Ultrasonics is applied to all areas of processing and manufacture

including plastics, food cutting and processing, high performance

materials for aerospace, automotive and general industries. |

We are now trading as InControl Ultrasonics Ltd. FFR Ultrasonics is the UK's leading innovator in Patented High Power Ultrasonic

Technology. A completely independent company, FFR offers the complete service in ultrasonic technology in the fields of plastic welding, cutting and fluidsonics (industrial sonochemistry

or processing), with particular expertise in customer application development, R&D and consultancy.

FFR Ultrasonics was founded in 1985 and has almost 20 years of experience to call on.

Dr Frank Rawson as

FFR's innovator has patented several unique ultrasonic processes giving

FFR a position of prominence in leading ultrasonic innovation in Europe. |

|

|

HIGH

POWER ULTRASONICS

For Plastics and Liquids

|

| |

|

|

UNIVERSAL ULTRASONIC CAPABILITY |

| |

|

|

|

TOTAL

SUPPORT |

|

Plastic Welding Systems

Fluidsonics Ultrasonic

Cutting Hire of Systems

Horns and Jigs

Special Systems

|

| |

|

|

| |

|

|

PLASTIC WELDING SYSTEMS

Available range:

20kHz from 500 to 4000 watts, 35kHz at 500 watts with integrated

generators. The 20 kHz models are suitable for a wide

range of general purpose welding, while the 35kHz unit is ideal for

precision welding of delicate parts.

DELTA 2000 and MINI

DELTA 9500

Multi‑head bench mounted systems and handguns

The latest technology with auto tuning solid state circuitry is

incorporated into the FFR ULTRASONICS range of thermoplastic

welding systems. Using single pillar pneumatic press and optional

microprocessor control of the welding System gives precise

control of the welding operation for consistent and quality assured

results.

Also available is the DELTA 2000 Series �H� frame 500mm

stroke welding system |

JOINT DESIGN AND

WELDING TYPE

Direct, spot welding and riveting

Energy director joint

Shear joint

Hermetic seal

SHORT AND LONG TERM

HIRE

All systems are

available for short or long term hire.

|

|

|

| |

|

Mini Delta 9500 Family |

| |

|

|

| |

|

|

|

FULL CONTRACT WELDING

SERVICE

Plastic

welding division offers a subcontract ultrasonic welding service: small,

one off batches to large volume, regular call off quantities. Please ask

for details. |

|

|

| |

| |

MINI & MICRO DELTA

9500 HAND GUN SYSTEMS

|

| CUTTING AND WELDING |

|

PLASTIC WELDING

APPLICATIONS |

| |

|

|

| This

powerful and versatile 35kHz ultrasonic handgun is simple to use and requires

only brief operator instruction. It is an ideal general purpose spot welder

for a wide range of thermoplastic materials and, with the quick change tips,

readily convert to a cutting tool capable of cutting materials ranging from

paper to ceramic tiles. |

|

Replaces adhesive joints

Millisecond machine welding times

Welds ABS, PC, Acetal, Nylon, Polypropylene, PS etc

The

most effective method of joining thermoplastic components

|

| |

|

|

| |

|

|

|

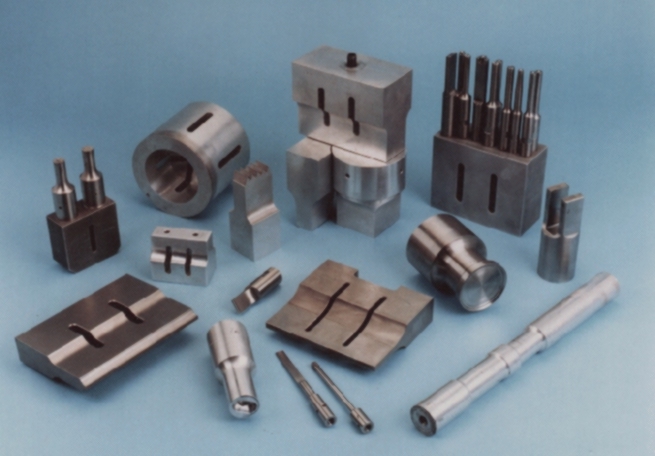

TOOLING, HORNS AND JIGS |

|

ULTRASONIC MACHINING,

DRILLING AND CUTTING |

| |

|

|

Rapid manufacturing

service for horns

to fit all popular welding Systems

|

|

For

ceramics, metals, textiles, plastics, food and paper

Profile cutting

Continuous cutting/slitting/multi head

Ultrasonic knives for hand held applications

Guillotine cutting up to 300mm (12") wide

|

| |

|

|

|

NEW |

|

CUTTING

|

|

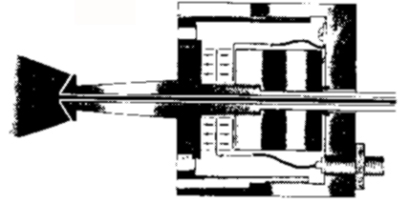

Rotating ultrasonic machining chuck to fit conventional and CNC machine

centres and robotic systems for the more difficult materials and 3D components

|

|

Cutters, Rapier, Sabre, Dagger and Radial cutting blades |

| |

|

|

| |

|

BESPOKE MACHINES FOR MANUFACTURING

INDUSTRY

Bespoke machines for inclusion into automated lines. Each head is capable

of full XYZ and tilt movement. The system is capable of switching five

heads from a single generator under full microprocessor control. |

|

|

| |

|

|

| |

|

|

| INDUSTRIAL APPLICATIONS |

|

|

| |

|

|

| Automotive |

| Consumer Durables |

| Building &

Construction |

| Plastic Components |

| Leisure |

| Agriculture |

| Packaging |

|

| Pharmaceutical |

| Aerospace |

| Toys |

| Confectionery |

| Boat Building |

| Food |

| Textiles |

|

TRAINING COURSES ON

HIGH POWER ULTRASONIC TECHNOLOGY

Courses

run in March, May and November each year. Also available: in‑company courses

tailored to specific needs.

THE COURSE has been planned to cater for designers and engineers with little

or no knowledge of ultrasonics.

BASIC 2 DAY COURSE

Introduction to ultrasonics

practice & theory, common applications including welding of metals & plastics,

types of equipment etc.

Using

ultrasonic equipment:‑ workshop & practical hands‑on experience, using several

different welding systems.

FLUIDSONICS

Fluidsonics is industrial scale sonochemistry ‑ high power applied to fluids

to cause a change in state of particles, molecules initial chemical reactions,

degas liquids by the action of cavitation and jet streaming.

Industrial processes and major water plc�s are increasingly using ultrasonic

energy to improve the performance of catalytic reactions and liquid processes

eg particle size reduction, spraying, atomising, mixing, emulsifying and

separating liquid and solids. A range of standard and customised systems are

available for these sonochemical applications.

| |

|

| SPRAYING |

|

| |

|

|

|

Spraying nozzles for fluids and water. Other systems

available for atomising molten metals and similar substances.

|

|

|

CLEANING

Ultrasonic cleaning, either aqueous or solvent based, scrubs the surface by

ultrasonic implosive and cavitation forces. This results in improved cleaning

and decontamination even on concealed surfaces that would be difficult or

impossible to clean by any other means. This process offers advantages in a

wide range of applications such as: optical, dental, precision engineering and

general laboratory work.

IT MAY LOOK CLEAN, BUT IS IT ULTRASONICALLY CLEAN?

|

AUTO HORN TUNER MODEL

AHT9801 FOR HORN MANUFACTURE

|

| |

|

|

|

For

optimum power transfer for successful thermoplastic welding, the HORNS

must be tuned to the system frequency and free from cracks or spurious

resonances. The design and manufacture of these horns is usually a

specialist service but with the FFR Ultrasonics Auto Horn Tuner it is

possible to fine tune simple horns and also check horns for defects. A

must for volume users manufacturing and tuning horns, the AHT 9801 can

soon pay for itself in reduced tooling costs and as a diagnostic aid.

FFR

Ultrasonics run training seminars on all aspects of power ultrasonics

including fluidsonics, horn design and manufacture

|

|

|

| |

|

|

|

FFR Ultrasonics run training seminars on all aspects of power ultrasonics

including fluidsonics, horn design and manufacture |

| |

|

|

SILENT SOUND ENERGY AT YOUR SERVICE |

| |

|