|

BENEFITS |

COMPLEMENTARY PROCESSES |

|

Significant cost/time saving |

|

Through feed system or batch processing |

|

Very high energy density |

|

Focussed ultrasonic energy |

|

Anti‑jamming/self clean |

|

Energy saving |

|

Avoids use of solvents |

|

100% environmentally friendly system |

|

95%

efficient conversion of electricity to ultrasonic energy |

|

|

CLEANING

Full range of industrial cleaners

|

|

SPRAYING AND ATOMISATION |

SONOTEC through feed nozzle.

Bespoke multi nozzle systems

Radial Cell and Processing Horns

|

| |

|

|

FLUIDSONIC PROCESSES |

EQUIPMENT RANGE |

| |

|

|

Particle size reduction |

|

De‑agglomeration |

|

Cleaning |

|

De‑watering |

|

Formation of solid/liquid suspensions |

|

Increase solid/liquid suspension life |

|

Filtration |

|

Initiating chemical reactions |

|

A range of equipment is

available.

1,2 and 3 kw focussed radial system: Pilot plant to 10 kw, production plant

to 100 kw

A bespoke design service is available to

design and supply processors to suit a specific application.

|

|

|

|

| |

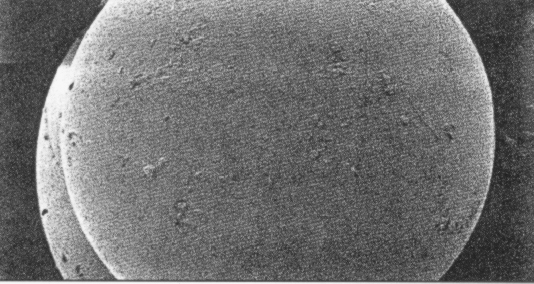

TiO2 CONTAMINATED RESIN

|

|

|

|

|

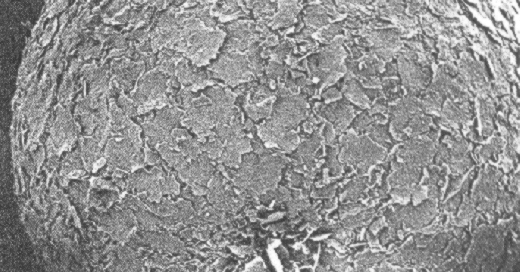

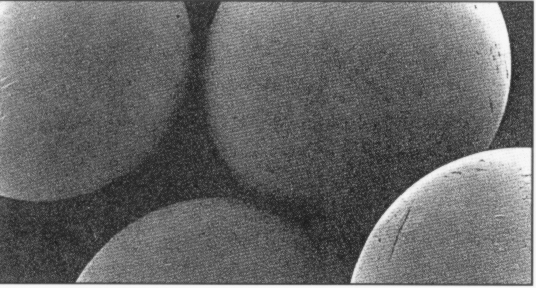

REPROCESSED RESIN |

|

| |

|

| |

|

|

APPLICATIONS IN VARIOUS INDUSTRIES

|

Chemical |

|

Building Materials |

|

Effluent treatment |

|

Metal casting |

|

Metal refining |

|

Pharmaceutical |

|

Paints and pigments |

|

Paper and pulp |

|

Food |

|

Water |

|

Glass |

|

PATENTED PROCESSES |

|

|

| |

|

|

Fluidsonics

Fluidsonics is industrial scale sonochemistry - high power ultrasonics

applied to liquids and gases. Normally encountered in the form of cleaning baths

and tanks, FFR holds a number of innovative patents employing the forces of

cavitation and streaming in novel ways.

|

| |

|

Case Study

|

|

Fluidsonics

Looking for ways of recycling existing materials, a major chemical company approached FFR with a view to cleaning the resin used in a processing plant. The resin particles had become coated with contaminant over a period of time, rendering them ineffective. Passing the particles in a liquid carrier through an ultrasonically vibrating cell horn cleared the surface contaminant which fell to the bottom of the container enabling the resin particles to be retrieved clean and ready for reuse.

FFR is currently collaborating with major PLCs in the water industry, and research groups on projects in the fields of public health and food processing.

|

| |

| |