|

| |

ULTRASONIC CUTTING

ULTRASONICALLY ENHANCED CUTTING SYSTEMS

FOR ALL MATERIALS

|

NEW PATENTED CONCEPTS

|

|

|

|

|

CUTTING PROCESS

|

|

|

|

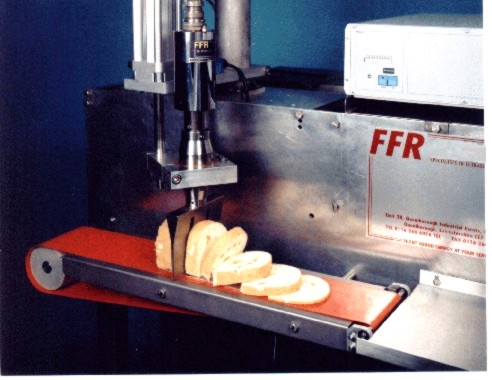

A

dramatic reduction in cutting forces enables soft products to be cut with

minimum distortion. Particularly suited to food products where the self

cleaning blade and no smearing of product is advantageous giving

exceptionally high cut quality

|

|

|

| |

|

|

| |

|

|

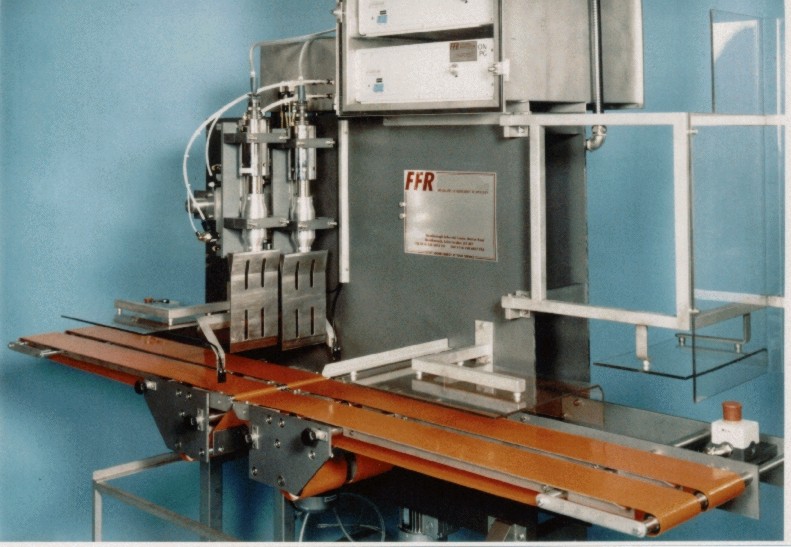

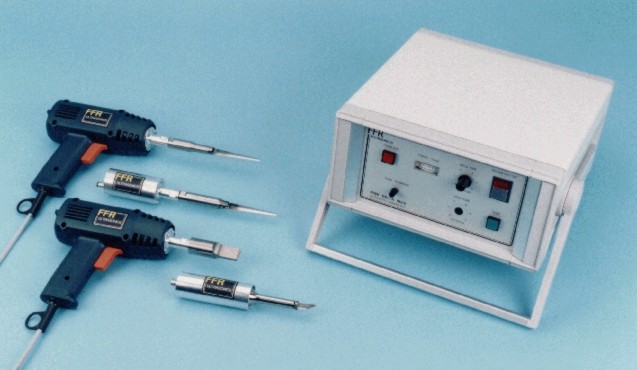

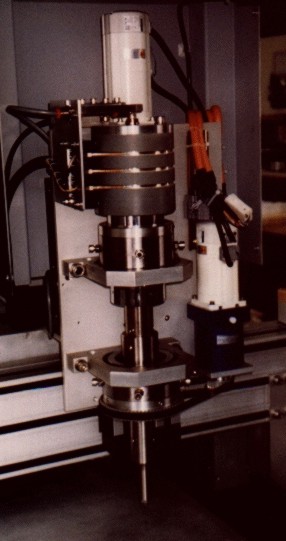

MINI DELTA 9500 SERIES

|

|

|

|

35

kHz 500 watt ultrasonic cutting system gives the choice of 4 hand held

guns or plant mounted, which power a 76mm sabre blade and are lightweight

and portable.

They are extremely versatile, cutting a wide range of material. Choice of

pistol, small NS, large or small trim knife guns

|

|

|

|

|

BENEFITS

|

Faster

cleaner cutting |

|

Seals

material on both edges thereby eliminating fusing operation (on

thermoplastics) |

|

Can be

multi headed |

|

Can be

fully automated |

|

Very

high cut quality |

|

Minimal

scrap and waste |

|

Can be

fully automated |

|

Self

cleaning blade |

|

APPLICATIONS IN VARIOUS

INDUSTRIES |

| |

|

|

Automotive |

|

Aerospace |

|

Toy |

|

Leisure |

|

Agriculture |

|

Fresh food |

|

Frozen food |

|

Plastics and rubbers |

|

|

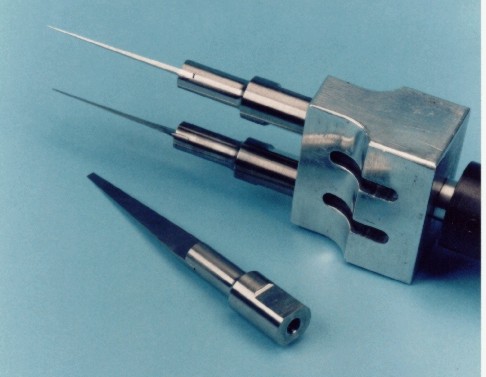

BLADE CONFIGURATION

|

|

|

|

|

|

Slitters � Multi blades �Saws

Cutting blades � Sabre

Cutlass � Excalibur

PANB � Guillotine � Rapier � Scalpel

Dagger � Radial

|

|

The

Sabre Blade For up to 30 Multi blade Plant Installations |

|

|

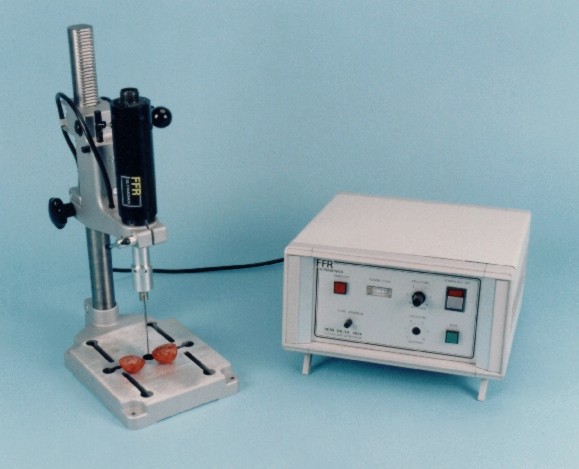

FOOD

APPLICATION

Ultrasonic cutting is particularly suitable for brittle bakery products, soft

sponges, creams and multi textured or sticky confectionery products

|

Bread |

|

Cakes |

|

Pizzas |

|

Frozen food |

|

Confectionery |

|

Vegetables |

|

Fish |

|

Meat |

|

COMPLEMENTARY

PROCESSES |

|

PATENTED PROCESSES |

|

Brittle and hard materials

|

Ultrasonic machining ‑ rotary |

|

Ultrasonic plunge slurry machining |

See

other leaflets |

|

|

|

|

Radial |

Sabre |

|

PANB |

Excalibur |

| |

|

| |

|

| |

|

| |

|

|

|

|

Food Cutting

Always in the forefront of technology ("the cutting edge"), FFR is the first

UK company to have ultrasonically enhanced cutting machines in action in the

UK's major food producing PLCs. Conventional cutting methods used in the food

industry all too frequently result in crushed or crumbled product with a

significant percentage of waste. Ultrasonic food cutting has many benefits for

the food producer:

| The quality of the cut face is visually excellent

|

| The cutting force required is significantly reduced

|

| Hard ingredients (eg nuts) can be cut in a soft matrix without dragging

|

| Smearing of one layer into another is reduced

|

| The blade is largely self-cleaning

|

| Crumb and debris is significantly reduced

|

| Brittle products have less tendency to shatter

|

The process is easily automated and is currently in use cutting products as

diverse as savoury snacks and pork pies, cream slices and cheesecake.

|

|

|

FFR Ultrasonics run training seminars on all aspects of power ultrasonics

including fluidsonics, horn design and manufacture |

| |

|

|

|

|

SILENT SOUND ENERGY AT YOUR SERVICE |

|