|

|

|

| |

|

|

|

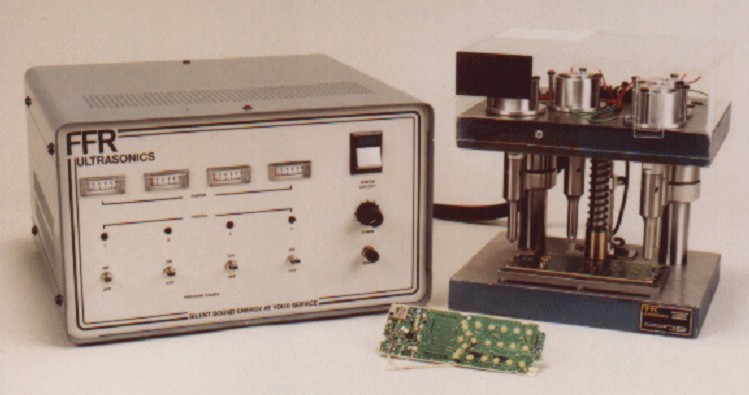

Mini & Micro Delta 9500 Systems |

|

|

|

|

THE ULTRASONIC PROCESS

|

|

|

Ultrasonic assembly is a fast, clean, efficient method of assembling or

processing rigid thermoplastic parts or films and synthetic fabrics. Various

ultrasonic assembly techniques are used by all segments of industry to join

plastic to plastic and plastic to metal parts or other non‑plastic

materials, mechanical fasteners, replacing or precluding the use of

solvents, adhesives, mechanical fasteners or other consumables.

Ultrasonics is mechanical vibrational energy converted to friction heat at

the joint surface. |

|

|

|

|

JOINT DESIGNS

|

Direct spot‑welding |

|

Energy director for amorphous thermoplastics |

|

Shear joint for semi crystalline thermoplastics |

|

|

|

BENEFITS

|

Energy efficient |

|

No

need for elaborate ventilation systems to remove fumes or heat |

|

High productivity with lower costs than many alternative assembly methods |

|

Ease of interface with automated assembly line production |

|

Hermetic joint |

|

|

|

THERMOPLASTIC WELDING & ASSEMBLY TECHNIQUES

|

|

Welding |

|

Swaging |

|

Textile cutting and sealing |

|

| Staking |

| Inserting |

| Spot Welding

|

|

|

|

|

DELTA 2000 AND 9500

FAMILY |

|

|

|

|

|

|

|

|

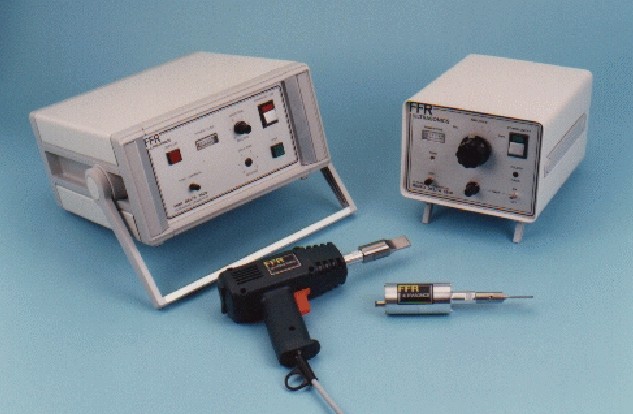

Mini Delta 9500 family

|

|

|

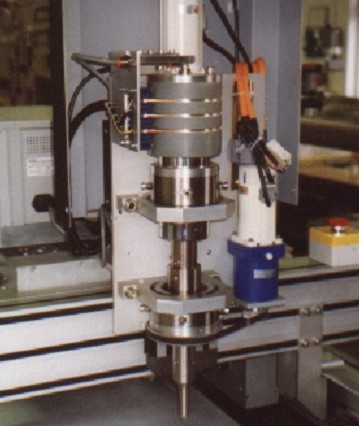

Delta 2000 Special

purpose

Rotating‑head Unit mounted

on XYZ table |

|

|

|

|

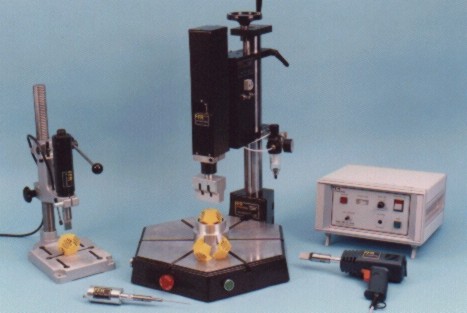

Special Semi‑automated

Precision Mini Delta 9500 35 kHz Twin Headed Machine |

Multi‑headed Micro Delta

System |

|

|

|

|

INDUSTRIAL APPLICATIONS

|

MODES OF APPLICATION

|

|

Automotive |

|

Medical |

|

Toys |

|

Consumer durables |

|

Electrical |

|

Business consumables |

|

Textiles and Plastics |

|

|

Manual ‑ Hand gun |

|

Semi Automated |

|

Fully Automated |

|

Robotic |

|

|

|

|

FULL TURN‑KEY PROJECT MANAGEMENT

Conceptual Studies Project Management

|

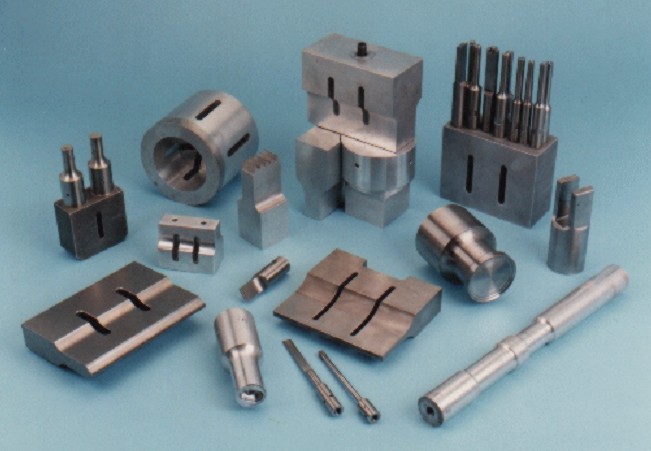

HORNS

|

|

The Complete Service for Horn Design, Manufacture

and Tuning |

|

Fully Automatic Delta 2000

20 kHz Machine |

|

|

|

|

Mini Delta

Best sellers in the FFR range are the Mini Delta 9500 family of versatile

hand held and small rigid press systems in the 35 kHz band. Designed for ease of

operation in welding and cutting application, there are currently in use in many

and various circumstances:-

| Cutting aeroplane ejector seat covers

|

| Welding motorcycle parts

|

| Welding electric toothbrushes

|

| Welding mobile phone components

|

| Cutting and sealing Velcro for medical applications, watch straps etc

|

| Several University R&D and experimental situations.

|

|

|

Delta 2000

These are the 20 kHz range of welding machines. They are designed for heavy

duty applications, particularly in the automotive industry and similar

environments. A number of these have been built into existing production lines

as specialised bespoke units.

|

|

Ultrafast

Unique to FFR, the newest members of the Ultrafast system can be inserted

using by a hand held ultrasonic unit, enabling greater versatility of

application. Beyond its original purpose, the Ultrafast has found many uses,

particularly for joining recycled plastics - industrial pallets and garden

furniture to name two.

|

Case Studies

|

|

|

Mini Delta

John Moor's University, Liverpool Art Department are using FFR equipment in experimental and development projects in the field of modern synthetic textile design and application, particularly looking at the possible applications in the fashion industry.

|

|

Ultrafast

Some 80 million pairs of ladies shoes is a good proof of the robustness of the Ultrafast ultrasonic stapling system. Originally conceived as the solution to the problem of high heels parting company with the shoe - usually at the most inconvenient moment. The system comprises a mechanically locking, self piercing staple inserted by ultrasonic vibration.

|

|

|

|

FFR Ultrasonics run training seminars on all aspects of power ultrasonics

including fluidsonics, horn design and manufacture |

|

|

|

SILENT SOUND ENERGY AT YOUR SERVICE |